Lanparte Old and New Rigs

-

>Take a look at the picture here. The screw does not drive directly into the ball joint. It drives a piece of rubber into the joint to create friction. It may work OK for a couple of times, but I think the aluminum chews into the rubber and makes it loose its grip.

Sorry I do not understand you.

Can you please show me this "piece of rubber "?

Wher do you see it?

@lanparte

>rubber washer

Where it is located on your picture?

>we do believe we can fix it.

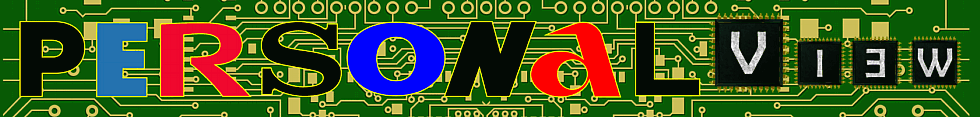

Can you clarify how problem with thumbscrew that is clearly bad made can be solved by such approach? -

I assumed that it was rubber gasket of some sort. There is a black rubber like substance that rubbed off into the ball head.

@lanparte....with all due respect, if I understand your rendering, I don't think this will work. You may have to put another screw on the opposite side, but even then, it will wear off. The way the ball head is designed, there are circumferential grooves only in one axis. Therefore, at best, it will only achieve strong grip along that axis. You'd have to also mill grooves in the perpendicular axis as well. I think Tilta type plates will be a bit less flexible, but much stronger. See the details in the picture

3959f601aa39d6578508222ae67774.jpg716 x 657 - 92K

3959f601aa39d6578508222ae67774.jpg716 x 657 - 92K -

>I assumed that it was rubber gasket of some sort. There is a black rubber like substance that rubbed off into the ball head.

If you look at the picture you'll see no such things.

I have similar handles (not made by Lanparte) and do not see any such problems.

Inside it has just metal half sphere. -

I hope the fix works when I get the rig. The tilta style of locking down is similar to how my pan handle locks down on my miller tripod head. It is very secure but they are quite well known for wearing down over the years until they start to slip and become useless.

-

@Vitaliy

>You need counterweight.

I found this, which should attach also to 15mm rods. Any other suggestion?

http://www.bhphotovideo.com/c/product/5194-REG/Manfrotto_172_172_Counter_Balance_Weight.html -

@lanparte: Received the rig today. Thumbs up for such a fast delivery. DHL Express rules m8. Sent on saturday, received on monday, wow!

The quality of the parts is outstanding for the price. Very precise cuts, you dont have to pull the screws too tighten to lock the rods, really nice matt finished black colour. All in all the "look & feel" is perfect and the price is more than fair. My advice for this product!

After the feedback in the past, i'm a little bit afraid of pulling the handles too tight and waiting for a solution for this, too. Your concept of a "force-support" is obvious and i got it, but adding a 2nd screw could be necessary as well ;) to be on the safe side. -

Handles need fixing.

I hope that Lanparte will present their current solution.

We'll wait until first customers will recieve replacements and go from where.

Un uptil then deal will remain closed, look at Wondlan rigs. -

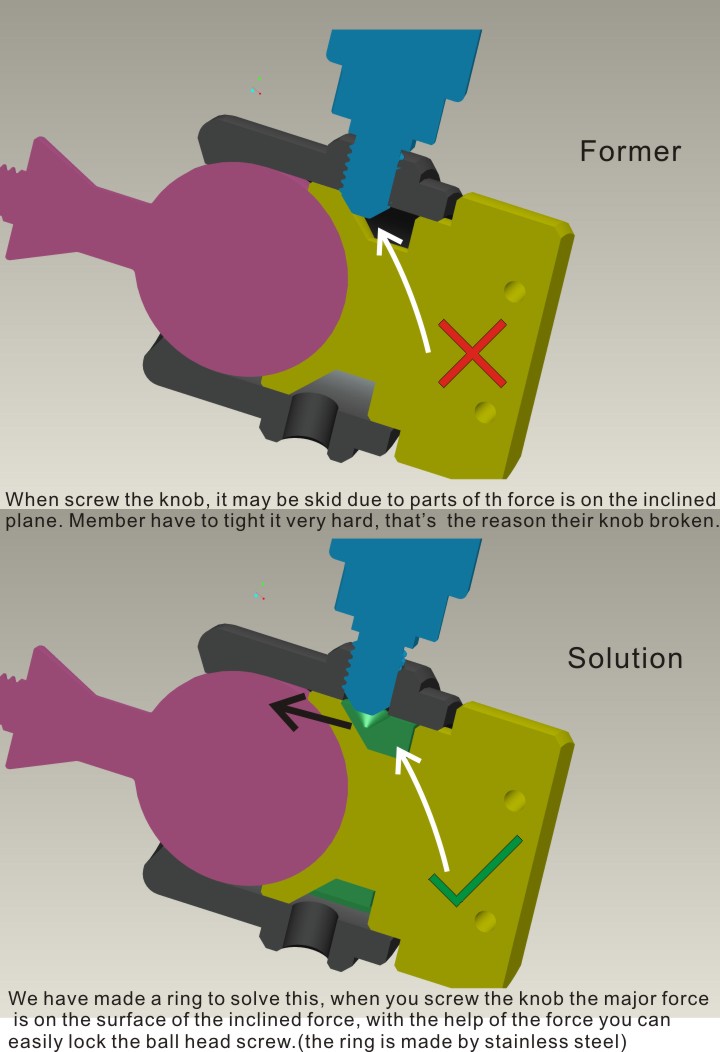

The hex screw in the knob is too thin, that's the reason why some guy's knobs met problem. Right now we use two screws to replace it, all the member who bought the rig will get the replacement. We will ship the replacement this week.

-

The hex screw in the knob is too thin, that's the reason why some guy's knobs met problem. Right now we use two screws to replace it, all the member who bought the rig will get the replacement. We will ship the replacement this week.

I missed the pics yesterday

1.jpg720 x 481 - 86K

1.jpg720 x 481 - 86K

2.jpg720 x 480 - 96K

2.jpg720 x 480 - 96K

3.jpg720 x 360 - 76K

3.jpg720 x 360 - 76K -

@lanparte

will you still use the stainless steel ring in the pall joint, apart from the replacement of the thumbscrews?

seems to make perfekt sense.

-

anybody received the new screws already?

-

I should get mine this weekend and will do an update review.

-

Received my new Thumbscrews today, but unfortunately I have receive a second Offset clamp instead of a straight clamp...

Anyways,while the new screws are definitely an improvement to the sitiation before, I am still not perfectly happy with it.

The ball joint is very stable when you have the handle straight at 180 degrees, just as the above test suggests.

But normally you would use the rig with the lower handle in a 90-120 degrees angle, and in that position the problem remains, that the handle is not really staying in the locked position when you move the loaded rig around.

I thought it probably has to do with the groovings in the ball, which are only in the top part of the ball-joint.

Also I thought the suggested stainless steel ring seemed to make sense, as the thumscews leave quite some marks in the aluminum counterpart. Or maybe the plastic-material in the counter half shpere does not provide enough grip...

@lanparte

did the ring-solution not work for you in your tests?

P1060857.JPG2400 x 1600 - 288K

P1060857.JPG2400 x 1600 - 288K

P1060858.JPG2400 x 1600 - 274K

P1060858.JPG2400 x 1600 - 274K

P1060859.JPG2400 x 1600 - 281K

P1060859.JPG2400 x 1600 - 281K -

-

Well just received mine. Very well packed and am quite impressed by the rig. Finish seems refined, screws tighten without too much pressure and the rig feels solid in the hand. The handles seem solid to me, they don't need to be over tightened to feel locked in, but time will tell whether they hold up. I'm not carrying much weight though, just the 7d, lens, follow focus and the lcdvf viewfinder.

Overall very happy with the purchase. -

I am really liking the looks of this rig. I'm interested!

-

Had another shoot with the rig today.

I still like the look and feel and the general quality of the parts.

But the problem with the moving handles remains.

This time we only had a 5D and follow focus mounted, but even in this lightweigt set up, the ball-joint does not stay in it's locked position.

Especially when you want to operate the follow focus and hold the rig only with one handle.

In fully loaded setup (Af100, Monitor, Mattebox...) it's unfortunately not a workable solution at all with this kind of handles.

@Vitaliy_Kiselev

you said you don't have this problem with your rig. Who is manufacturer of your handles?

@lanparte

do you think you can solve this problem? -

@spreegurke

As I said, make video of this problem and send a link to Lanparte support.

I can't help you here. -

Here's my quick update on the handle issue:

-

@jaecjaec

thanks for your review, but tightening the screws with a hex key doesn't make to much sense when your shooting out in the field and need to make adjustments here and there.

also in your test you have the handle-bars straight at 180 degrees, which you will will normally never have when shooting with the rig. Like I mentioned above, the joint holds up well in that position, even id just locked with the thumbscrews.

If you mount the handles in "shooting position" like in the picture, it's more or less impossible to lock them firmly with loaded rig and thumbscrew.

03cf2b43be02c36e94a2cd19d4a850.jpg628 x 812 - 78K

03cf2b43be02c36e94a2cd19d4a850.jpg628 x 812 - 78K -

@spreegurke I wish these screws are easier to tighten as well. as for the position of the handle, it should not make much of a difference how you have it. I showed it straight out, since that would theoretically generated the most torque on the joints. As you can tell, my rig is extremely heavy. I had a hard time even holding it in that position. It felt like 15kg at that angle. I have a cavision handle on my second rig, I can tell you that if I put that much torque on it, it wouldn't hold any better. There must be something else wrong with your handle. I'd talk to Jerry at Lanparte to see if he can do something for you.

-

I think I figured out why the screws on my handle are so hard to tighten. I looked at the package that Jerry sent to me, and there was a drill/tap bit. The original tap holes are just a tiny bit too small. I was supposed to tap out a larger whole. Aluminum is pretty soft so apparently the new screws are some what self tapping, which explains why they are so tight.

-

same here. just replaced the new scres but still the problem that i cannot pull the screws tight enough to "lock" the handles. it always depends in which angle you are with the handbars.

should we really enlarge the whole by drilling? i feel a bit insecure ;)

after enlarging the wholes, could we pull the screws more tighten? -

I retapped the threat in the rig, but it doesn't change a thing... of course the new thumbscrews run easier, but in terms of locking the handle bars it doesn't help.

I just wrote Jerry from Lanparte to see, what his opinion is on that. -

I have a handle bent up so it's right beside the follow focus wheel and I've noticed it slips if I pick my rig up by it. I think an easy fix for lanparte would be to provide friction grooves over the whole ball socket for the screws to grip into instead of just the top half.

Start New Topic

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List23,964

- Blog5,723

- General and News1,342

- Hacks and Patches1,151

- ↳ Top Settings33

- ↳ Beginners254

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,361

- ↳ Panasonic990

- ↳ Canon118

- ↳ Sony154

- ↳ Nikon96

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm99

- ↳ Compacts and Camcorders299

- ↳ Smartphones for video97

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras121

- Skill1,961

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors191

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips267

- Gear5,414

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,579

- ↳ Follow focus and gears93

- ↳ Sound498

- ↳ Lighting gear314

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff272

- ↳ Power solutions83

- ↳ Monitors and viewfinders339

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear560

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,319