It allows to keep PV going, with more focus towards AI, but keeping be one of the few truly independent places.

-

AMSL

ASML Holding NV, a crucial supplier to Samsung Electronics Co. and Taiwan Semiconductor Manufacturing Co, refrained from providing guidance for the second quarter amid uncertainty following the coronavirus pandemic

First-quarter revenue came in at 2.4 billion euros ($2.6 billion) with net bookings of 3.1 billion euros, including 1.5 billion euros of EUV systems. First-quarter gross margin was 45.1 percent. ASML last month cut its revenue outlook for the first quarter and halted share buyback plans after complications from the novel coronavirus caused supply-chain problems and shipment delays. It had previously forecast revenue of as much as 3.3 billion euros with a gross margin of as much as 47%.

This can be interesting, being monopoly company now is major obstacle on mass dvelopment of latest technologies across the world. Breaking and crushing this company, as well as stealing all information can be top priority for number of countries now, including China.

-

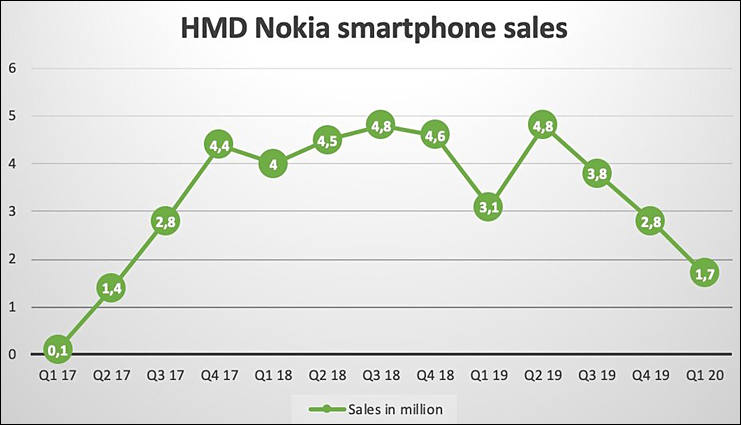

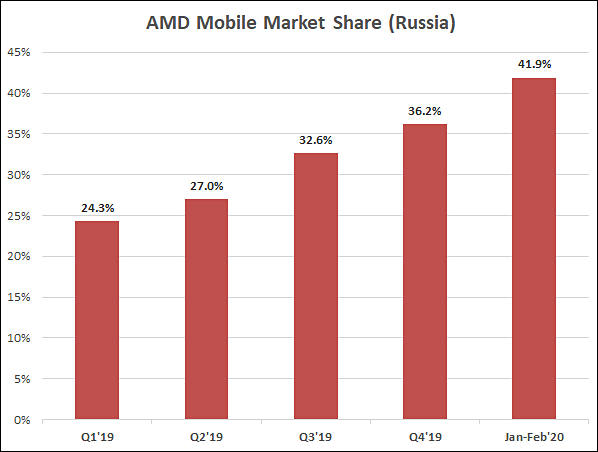

Bad news for Intel, and same thing happens in the server segment.

Coronavirus tripled AMD market share speed increase and it can reach 25% in September already (with >50% in the most competitive cloud and hosting contracts).

sa12756.jpg598 x 452 - 36K

sa12756.jpg598 x 452 - 36K -

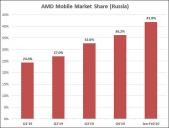

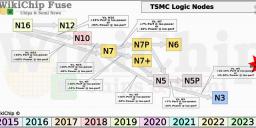

Something is up with 3nm TSMC process

TSMC has decided to stick with FinFETs for N3 owing to the maturity of the technology. Experts are of the opinion that sub-5 nm nodes will require major innovations with materials and structures. TSMC claims that N3 will provide a 10-15% speed improvement at iso-power or 25-30% power reduction at iso-speed.

This year TSMC already fucked up 7nm+ EUV process being unable to provide working chips for AMD.

And here we can see their strange idea to use FinFET for 3nm. In reality we can see some marketing related bullshit instead of 3nm.

sa12784.jpg800 x 368 - 59K

sa12784.jpg800 x 368 - 59K -

TSMC has seen the installation of its advanced 3nm and 5nm process capacity disrupted by lifting equipment delivery delays.

-

TSMC has kicked off its 2nm process R&D, and is progressing in research and exploratory studies for nodes beyond 2nm, the foundry has diclosed in its annual report to shareholders.

-

Due to coronavirus Intel will delay 10nm production of some products.

7nm will be also delayed, up to1 year in practice (in reality Intel do not have any real functioning 7nm and due to EUV usage it is not clear if they will ever have).

-

Huawei paid to TSMC more than $5,1 billions for mostly smartphone chips. Only Apple paid more to chipmaker ($8,24).

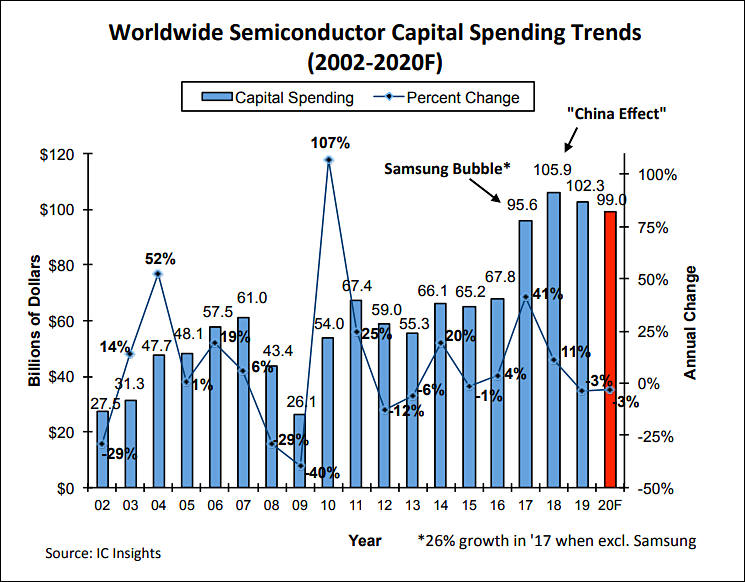

Hence problems of smartphone makers can lead to huge issues of TSMC, as chipmaker now inject huge profits it get from premium smartphone to finance expensive equipment (due to total monopoly profits on it also are astronomical).

Destruction of TSMC leadership can be very good to market.

-

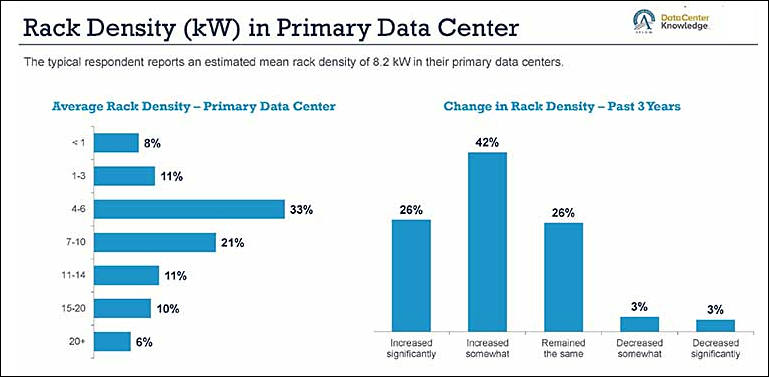

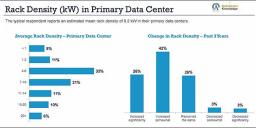

Datacenters badly need less power hungry things.

Especially neural network based things are very inefficient.

sa12871.jpg769 x 377 - 40K

sa12871.jpg769 x 377 - 40K -

From Samsung PR

In the second half, to address current uncertainties, the Foundry Business will focus on diversifying applications beyond mobile to include areas such as consumer and computing applications. It will also continue investing in advanced processes for the future and will start mass-producing 5nm products this year and focus on the development of GAA 3 nm process.

-

Samsung said in today's financial report that it will conduct mass production of 5nm EUV by the second quarter of this year, that is, before July, and thereby strengthen its leading position in the field of EUV technology. In addition, Samsung will focus on the development of 3nm GAA (surrounding the gate transistor), and talk about the FinFET (fin field effect transistor) technology used by TSMC.

https://www.chinatimes.com/realtimenews/20200429002735-260410?chdtv

Samsung actually lost 7nm orders from Nvidia being unable to make reliable chips for more than a year using it.

Now they claim big things about 5nm, but it can also fail miserably.

-

Sales of smartphones in the China market slumped by 51.9% sequentially and 38.9% on year to their lowest quarterly levels of recent years in the first quarter of 2020 due to the impacts of coronavirus pandemic and seasonality,

Up to 60% of all TSMC and similar firms expenses had been financed from buyers of top smartphones.

-

Again on Moore law

Chiplets effectively bypass Moore's Law by replacing a single silicon die with multiple smaller dice that work together in a unified packaged solution. This approach provides much more silicon to add transistors compared to a monolithic microchip. As a result, chiplets are expected to allow a return to the two-year doubling cycle that has underpinned the economics of the semiconductor business since 1965.

"When semiconductor pioneer Gordon Moore first published his theory about semiconductor advancement, he provided a key forecasting benchmark that set a development cycle for the entire tech industry," said Tom Hackenberg, principal analyst, embedded processors, Omdia. "From software developers, to system designers, to tech investors, everyone for decades counted on the swift two-year schedule defined by Moore's Law. With the arrival of chiplets, the semiconductor business and those that depend upon it now have the opportunity to return to the customary rate of progress that has driven so much economic value for the overall tech industry."

Chiplets are experiencing adoption in more advanced and highly integrated semiconductor devices, i.e., microprocessors (MPU), system-on-chip (SoC) devices, graphics processing units (GPU) and programmable logic devices (PLD). The MPU segment represents the largest single market for chiplets among different microchip product types. The global market with chiplet-enabled MPUs is expected to expand to US$2.4 billion in 2024, up from US$452 million in 2018, according to Omdia.

"To remain competitive, MPU makers must always stick to the cutting edge of semiconductor manufacturing technologies," Hackenberg said. "These companies have the most to lose from the slowdown in Moore's Law. Because of this, these companies are among the earliest adopters of chiplets and are likely to be the primary contributors to chiplet standardization efforts."

MPU suppliers such as Intel and AMD are the early innovators building proprietary advanced packaging chiplets. Intel is also a member of the Open Compute Project, Open Domain-Specific Architecture (OCP ODSA) foundation, which is promoting the development of standards and technologies that are helping to enable advanced packaging strategies.

With the early adoption in MPUs, the computing segment is expected to be the dominant application market for chiplets through 2024, Omdia noted. Computing will account for 96% of revenue in 2020 and 92% by 2024.

Over the longer term, Omdia expects chiplet revenue to continue to expand and reach US$57 billion in revenue by 2035. Much of this growth will be driven by chiplets that serve as heterogenous processors, i.e., chips that combine different processing elements, such as applications processors that integrate graphics, security engines, artificial intelligence (AI) acceleration, low-power internet of things (IoT) controllers and more.

"Chiplets may not single-handedly save Moore's Law, but they do represent an innovative, emerging approach that help advance new packaging technologies, new design strategies and new materials," Hackenberg said. "This exciting new approach also may enable a more competitive landscape with diverse contributors. Chiplets will bolster the cadence Moore conveyed in his original 1965 article. The import of that original statement was not really about how microprocessors grow in performance. Rather, it was about establishing an industry guideline for a cadence that system designers, software developers and investors could count on to drive the innovation engine. This is the aspect of Moore's Law that will live on."

Too much hope for chiplets. They hope that issues with new processes could be hidden, no they won't.

-

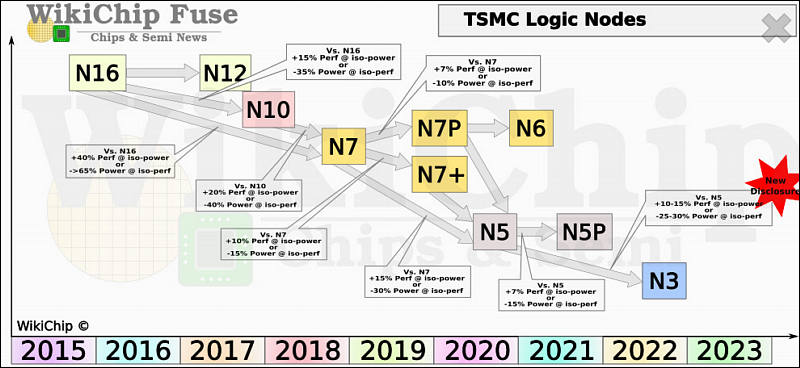

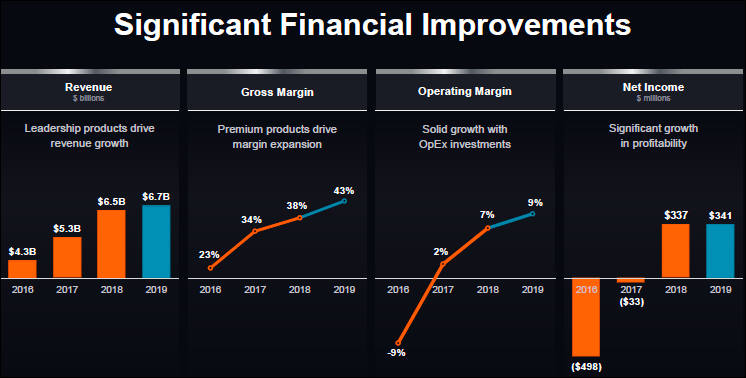

AMD feeling good

But due to issues with smartphones they will be forced to inject more in TSMC and marketing.

sa12999.jpg746 x 378 - 51K

sa12999.jpg746 x 378 - 51K -

Wall Street Journal sources say the White House is talking to Intel and TSMC about setting up US chip factories. While Intel already has a US presence, its discussions revolve creating a foundry that other companies could use for their products.

In the time of dangerous Chinese manufacturers rise (now only equipment control limit this rise) Wall Street Journal sources say the White House is talking to Intel and TSMC about setting up US chip factories. While Intel already has a US presence, its discussions revolve creating a foundry that other companies could use for their products.

This can actually put big stick in both TSMC and Intel front wheels, as they now will be forced to move best factories and make new ones in mostly in US, this means 3-4 years delay that can become fatal.

-

The foundry leader TSMC 5nm will enter the mass production phase in the third quarter. Although the main orders in the second half are still Apple and Huawei Hisilicon, including Qualcomm, MediaTek, Xilinx, Broadcom, Supermicro. In addition, the market has reported that Intel is expected to commission some of the 5nm chips by TSMC.

It is no sign of working 7nm process in Intel. Even 10nm still sucks badly.

With present issues in place we can have Intel leaving leading pack as soon as next year. Cancelling 7nm altogether similar to Showing results for GlobalFoundries.

-

Hygon Dhyana (threadripper 1st gen sold to CHinese) will move to 7nm soon. Samsung or TSMC or both will make them.

Big danger here is that it won't AMD team who will do redesign for completely new process, but new team of more than 500 Chinese engineers.

AMD seems to make huge error providing all documentation and signing on terms where they can't stop it now.

CPU can jump to 32 cores even. But still will be using same mount.

Compatibility to older x399 chipset can be also in Chinese plans as they can sell them internationally in this case.

-

Intel's fate

Wall Street semiconductor analysts have mixed feelings about the notion of Intel (ticker: INTC) jumping into the contract chip-making business in competition with Taiwan Semiconductor Manufacturing (TSM), which controls more than half of the global market,

Christopher Danely asserts in a research note Tuesday that a new Intel foundry would have a “very low chance of success.” On the one hand, he thinks the foundry market “is the only growth opportunity for Intel as it can leverage its technology leadership and experience in manufacturing.” He also notes that Taiwan Semi, also known as TSMC, operates with much higher operating margins than Intel.

The company is having issues with both seven- and 10-nanometer manufacturing lines.

Building a new, cutting-edge fab will take up to three years—and capital, between $10 billion and $20 billion. Intel has tried several times before to enter the foundry business, but hasn’t been successful,

Longer-term, Arya sees the possibility of Intel breaking up its design and manufacturing arms into separate companies.

This can happen as early as next year.

-

TSMC and surprise strange news on US plant

Taiwan Semiconductor Manufacturing Co plans to build an advanced chip factory in Arizona. The plant would make 5-nanometer transistor chips for TSMC.

TSMC’s board made the decision to build the plant earlier this week at a meeting in Taiwan and may officially announced the plans as early as Friday.

The plans call for the factory to begin producing the chips by the end of 2023.

This fully contradicts all other reports.

But it can be special plot made by Apple and TSMC to explain low volume of 5nm production later this year and next year, as well as very big delays with further processes.

Something is happening with TSMC, as it lost around 30% of income in last months. Most probably we see now attempt of US to transfer newly printed money directly to most valuable asset they have.

-

TSMC today announced its intention to build and operate an advanced semiconductor fab in the US with the mutual understanding and commitment to support from the US federal government and the State of Arizona.

This facility, which will be built in Arizona, will utilize TSMC's 5nm technology for semiconductor wafer fabrication, have a 20,000 semiconductor wafer per month capacity, create over 1,600 high-tech professional jobs directly, and thousands of indirect jobs in the semiconductor ecosystem, the Taaiwan-based foundry house said.

Construction is planned to start in 2021 with production targeted to begin in 2024. TSMC's total spending on this project, including capital expenditure, will be approximately US$12 billion from 2021 to 2029. TSMC said this US facility not only enables the company to better support its customers and partners, it also provides foundry house with more opportunities to attract global talent. This project is of critical, strategic importance to a vibrant and competitive US semiconductor ecosystem that enables leading US companies to fabricate their cutting-edge semiconductor products within the US and benefit from the proximity of a world-class semiconductor foundry and ecosystem, TSMC said.

TSMC said it welcomes continued strong partnership with the US administration and the State of Arizona on this project, which will require significant capital and technology investments from TSMC. The company said the strong investment climate in the US, and its talented workforce make this and future investments in the US attractive to TSMC.

Board of directors changed opinion in 48 hours. As soon as real owners called.

-

Tragedy of TSMC

Taiwan Semiconductor Manufacturing Co., the world biggest contract chipmaker, has halted new orders from Huawei Technologies in response to tighter U.S. export controls aimed at further limiting the Chinese company's access to crucial chip supplies.

Huawei is TSMC's second-largest client only after Apple, accounting for 15-20% of its annual revenue. Huawei also accounted for up to 20% of SMIC's revenue, according to a Bernstein Research estimate.

According to the document posted online by the U.S. Commerce Department Bureau of Industry and Security, chip shipments bound for Huawei that went into production before May 15 and will ship before midnight Sept. 14 are not subject to the new rule. A license will be required for all other shipments.

Impact of this decision will be unprecidented.

It can be also only measure that could save Intel and buy 1-2 more years by keeping TSMC from moving forward.

-

Got very interesting opinion today in talk

US goverment asked biggest bansk and funds for heavy investments in AMD 3-4 years ago as they need AMD during later stages of trade war. As well as same investments in TSMC.

US hoped that TSMC being largest manufacturer and AMD/Nvidia/Apple as biggest clients could help them avoid confrontaion with China and damage to US firms.

Recent Trump move can be actually aimed to fully destroy democratic party plan and largest California companies plans. Such way Trump goes into open confrontaion that can lead in few monst to horrible consequence for Apple, AMD and alike.

Chinese can move as far as block some of Taiwan exports to US.

-

GLOBALFOUNDRIES® (GF®), the world's leading specialty foundry and the leading U.S. pure-play manufacturer of semiconductors, today announced plans to implement export control security measures at its most advanced manufacturing facility, Fab 8, in Malta, New York. GF will bring its Fab 8 facility into compliance with both the U.S. International Traffic in Arms Regulations (ITAR) standards and the Export Administration Regulations (EAR), making the company the most advanced ITAR foundry in the country. By taking this significant step, GF deepens its partnership with the U.S. Department of Defense (DoD) and the U.S. defense industrial base, and further supports ongoing development of new assurance approaches in support of national security objectives.

These new control assurances, which will go into effect later this year, will make confidentiality and integrity protections available for defense-related applications, devices or components manufactured at GF’s Fab 8 facility. To date, GF has invested over $13 billion in Fab 8 and this is a significant step to serve the U.S. government and its technology needs for decades.

Senate Democratic Leader Chuck Schumer commented, “I have always been a strong believer that the most secure way to manufacture semiconductor chips is to do so here in the U.S. I have also been a champion of GLOBALFOUNDRIES and applaud their efforts to provide ITAR and EAR compliant manufacturing to the U.S. Government. In partnership with GF, New York State leads the nation in secure semiconductor manufacturing.”

Company can have US military as their main clients within 2 years.

TSMC story can also explain why all of the sudden GF dropped their own 7nm process and AMD had been ordered to use TSMC.

China goal now is to use any means, dirty tricks and open military force to destroy US - TSMC deal and also find weak spots in other US mased manufacturers logistics.

-

SEMICONDUCTOR WAR UPDATE

Samsung is the top global producer of computer memory, smartphones and displays. Samsung is now spending $116 billion to compete with TSMC and Intel. They are building a cutting-edge chip production line south of Seoul – scheduled to start in the second half of 2021. Samsung will use extreme ultraviolet lithography to make chips for applications from 5G networks to ultra-high-performance computing.Samsung wants to take on Taiwan’s TSMC, producing for international clients. That will mean, essentially, China, with customers including Qualcomm.In parallel, Huawei bought a six-month supply of semiconductors from TSMC before the latest US sanctions. That will assure mid-term, but what matters is how China is catching up on semiconductors and chips at breakneck speed.That will require hundreds of thousands of engineers. And China, according to an Apple source, does have them. The source says that China has such massive engineering depth now that Apple itself can go NOWHERE ELSE to solve major engineering problems.This kind of depth in the US simply does not exist. US engineering schools have mostly foreign engineers. If some of them did not stay in the US, Exceptionalistan would be in deep trouble.This was confirmed to one of my sources by a top exec in a major, advanced US tech company: when he looks around the massive floor of engineers he supervises, no less than 2/3 are from China and India.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List23,970

- Blog5,724

- General and News1,346

- Hacks and Patches1,153

- ↳ Top Settings33

- ↳ Beginners255

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,360

- ↳ Panasonic990

- ↳ Canon118

- ↳ Sony155

- ↳ Nikon96

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm100

- ↳ Compacts and Camcorders300

- ↳ Smartphones for video97

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras117

- Skill1,961

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors191

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips267

- Gear5,414

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,579

- ↳ Follow focus and gears93

- ↳ Sound498

- ↳ Lighting gear314

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff272

- ↳ Power solutions83

- ↳ Monitors and viewfinders339

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear560

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,319