-

Follows0Replies0Views645War: Chinese semiconductor business is feeling good

-

Although some of its key semiconductor industry players were put on the Entity List by the US government since 2019, China managed to register double-digit growth in the revenues of all of its semiconductor sub-sectors in 2020, pushing up global market shares to challenge Taiwan and the US, according to several recent reports.

If the robust growth continues, China's semiconductor industry will grow rapidly in the next decade and by 2030 will become a world champion in semiconductor manufacturing, seizing a 24% global market share, as previously predicted by the Semiconductor Industry Association (SIA).

According to an SIA blog, the semiconductor industry in China grew 30.6% in 2020 to reach $39.8 billion in total sales, representing robust annual growth of 36%, 23%, 32%, and 23% for the fabless, IDM, foundry, and OSAT sectors, respectively.

China registered 9% of the global semiconductor market share in 2020, surpassing that of Taiwan for the second year in a row. It is likely to overtake Japan and Europe soon, as the global market shares of the semiconductor industry in the two major economies both stood at 10%.

China's fabless semiconductor sub-segment ranked third after the US and Taiwan, taking 16% of the global market share, up from 10% in 2015, even though it was subject to tightened chip export control restrictions.

In terms of wafer capacity increase, China accounted for 26% of the worldwide total, according to IC Insights and SIA, while its top 3 outsourced semiconductor assembly and testing (OSAT) companies collectively garnered more than 35% of the global market share.

China has already announced US$26 billion in new planned funding for 28 additional fab construction projects in 2021, mostly focusing on mature processing nodes.

-

-

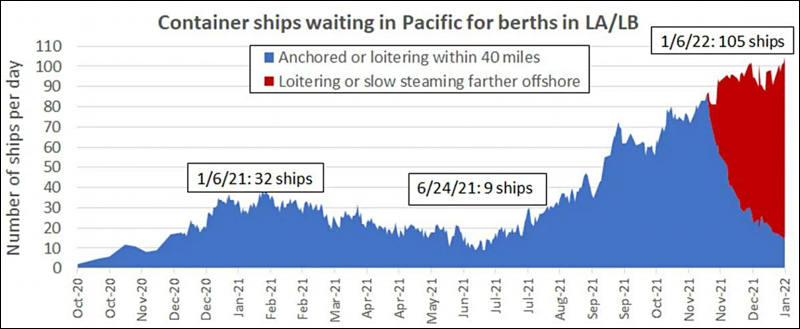

Follows0Replies2Views1.7KMAGA: Situations with ships is very bad2 comments 3 comments Vitaliy_KiselevJanuary 2022Last reply - January 2022 by DrDave

Subscribe to this blog

Subscribe to this blog

-

-

Follows0Replies0Views697Cameras Sales: 2021 December Japanese sales, Map Camera

-

Best selling new cameras

- Sony α7 IV

- Nikon Z 9

- Canon EOS R6

- Canon EOS RP

- Fujifilm X-E4

- Nikon Z fc

- Sony FX3

- Sony VLOGCAM ZV- E10

- Ricoh Imaging RICOH GR IIIx

- Canon EOS R5

Best selling used cameras

- Sony α7 III

- Sony α7C

- Fujifilm X-S10

- OM Digital Solutions OM-D E-M1 Mark II

- Ricoh Imaging RICOH GR III

- Canon EOS R

- Nikon D750

- Fujifilm X100V

- Canon EOS RP

- Sony α6000

-

-

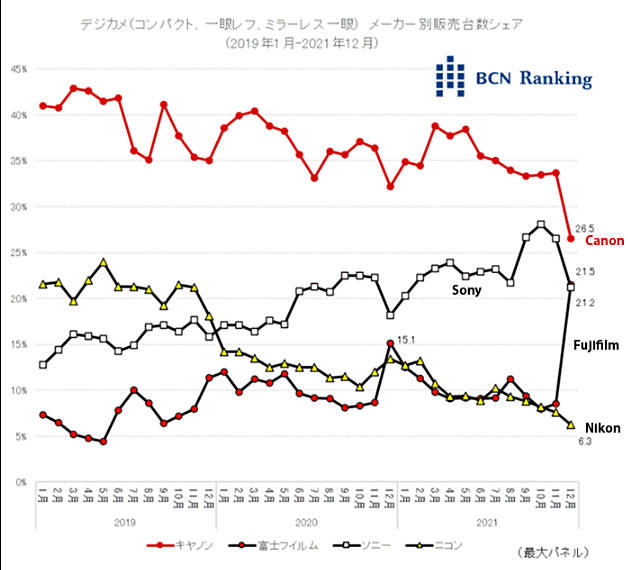

Follows0Replies3Views1.7KJapanese cameras market share by BNC Ranking3 comments 4 comments Vitaliy_KiselevJanuary 2022Last reply - January 2022 by AndrewReid_EOSHD

Subscribe to this blog

Subscribe to this blog

-

-

Follows0Replies0Views703Energy: Role of energy costs in basic materials

-

Cement: the technology is simple - we take almost any raw material, from limestone and clay to slag, which is nearby and cheap, we burn it into cement clinker. These are rotary kilns - for a 140-150m long kiln, the gas consumption is frantic, the temperature in the firing zone is kept up to 1700. The drives on the kiln are motors over 150kW. Plus transporters. Then grinding in ball tube mills is a huge consumption of EE. Well, there is also aspiration, filters, etc. Conclusion - raw materials cost a penny, 80 percent of the cost of cement - energy.

Glass: Stove-pool, we pour sand into it (mined, washed, classified, dried) plus soda (soda production is a separate song, there are shaft furnaces 40-80 meters high, the main costs are gas and EE) - EE and gas. Continuously melting raw materials and forming a bottle or pulling a sheet. Conclusion - raw materials cost a penny, 80 percent of the cost of both soda and glass itself are energy carriers.

Brick. Ceramics - clay, knead, knead again, and again knead, then mold, dry in huge dryers - it dried 10 times more than the oven. The energy carrier in the dryer is gas or electricity. There are combined ones. Dry for a long time. We take it out, then we burn it in a slot-hole tunnel kiln. Temperature - 950-1100. The heat carrier is gas. Conclusion - raw materials cost a penny, 80 percent of the cost of ceramic bricks - energy. Usually it is automatic plant - personnel costs a penny.

Silicate brick, gas silicate, foam concrete. Sand plus liquid glass (sodium silicate or potassium silicate, boiled into a liquid by steam, steam generators - EE) - mixed, molded, loaded into steaming chambers. Steam steaming - EE or gas. Gas silicate is a little different, but the general conclusion is that raw materials cost a penny, 80 percent of the cost are energy carriers.

Ferrous metallurgy. Cast iron - ore is mined, enrichment - washing, roasting requires lot of EE and gas. If a blast furnace, then coal plus gas plus petcoke, well, there are a lot of things and a huge amount of energy efficiency. If the convector is a jet of oxygen from above into the pot - EE plus gas. From cast iron to steel - or immediately after the convector, after a couple of warm-ups or, more often, chipboard - we melt cast iron plus scrap metal with coal and electric arc additives. Energy consumption is huge. What we pour into chipboard - ferroalloys (75-80% of EE in the cost price), carburizer, metal mirror heaters, etc. Conclusion - raw materials cost a penny, 60-65 percent of the cost of ferrous metal - energy. If we roll it into a product - heating, rolling - EE and gas.

Non-ferrous metallurgy, except for aluminum, is practically the same as ferrous metallurgy, only there are a lot more redistributions for the preparation of raw materials, the percentage of energy carriers in the cost is slightly less.

Aluminum - ore is mined, driven at the GOK to the state of electrocorundum, that is, electromelting and grinding to obtain a powder - electricity is practically the only consumable material. We load it into an electrolyzer (melt bath) and melt it with electricity, remove the alloy, roll it, stamp it. For aluminum - the main cost is from electricity consumption. I completely forgot - when melting, we add pure crystalline silicon, in which 85% of the cost is electricity cost.

All of the above furnaces (rotators, tunnels, glass melting baths, mines, blast furnaces, chipboard, electrolyzers, etc.) need a refractory lining. Refractories - magnesite, corundum, silicon carbide, fireclay, zirconium, diatomite, dinas, etc. - are all fired or melted in electric or gas furnaces. The consumption of energy for different refractories is different, but very large.

Chemistry - furnaces everywhere, fertilizers - furnaces and distillation, food industry - furnaces everywhere, sugar, by the way. Asphalt - well, yes, bitumen, crushed stone and sand.

The general conclusion is that every butt truck, glass bottle or beer can, candy or concrete step has a wild amount of Electricity and Gas invested in it! Just wild. Any change in the price at the initial stage entails the accumulated rise in price and the complete non-competitiveness of the goods.

-

-

Follows0Replies0Views693EU: Big rapid cuts in aluminium production

-

The rapid rise in electricity prices in Europe has led to a reduction in energy-intensive aluminum production.

Bank of America estimates that of Europe's total aluminum production of 4.5 million tons, about 650,000 tons have been cut so far, while CRU estimates 729,000 tons.

Below is a list of smelters that have reduced production.

ALCOA

In December, the metal producer entered into a deal to shut down aluminum production at its San Ciprian plant in Spain for two years. The annual capacity of the smelter is 228,000 tons.

ALDEL

The Dutch aluminum smelter in Delfzijl cut production in October. Its annual capacity is 150,000 tons.

ALRO

The Romanian metal producer is going to cut production by 60% in the first phase. Its annual capacity is 283,000 tons.

DUNKIRK

The 285,000-tonne-per-year Dunkirk ironworks in France said it would cut output by 15%.

NORSK HYDRO

The Slovalco steel plant will cut production to around 60% of its output, or about 70,000 tons of aluminium.

TALUM

The company has reduced production at its Slovenian steel plant by a third since November 1. It produced 114,581 tons in 2021, according to Talum.

TRIMET

The German metal producer cut aluminum production by 30% at its facilities in Essen, Hamburg and Weerde.

The Essen and Hamburg plants produce 165,000 tons and 135,000 tons of aluminum per year respectively, while the Wörde plant has a capacity of 95,000 tons.

UNIPROM

The KAP steel plant in Montenegro has been gradually reducing production since December 15. He cut production by about 35,000 tons.

-

-

Follows0Replies0Views633War: French Government wants elderly to die fast

-

In France, 530,000 older people aged 60 and over are in a state of "social death", that is, they never or almost never communicate with family members, friends, neighbors and other people.

This is 77 percent more than in 2017, according to a study by Les Petits Freres des Pauvres. Two million French people aged 60+ are isolated from their families and friends - up from 900,000 four years ago.

“Death doesn’t scare me. The way I live now is not life. I don’t see anyone,” said one of the participants in the study, Edith, 76 years old. The authors of the report explained this increase in the "socially dead" by the fact that the number of elderly people in general has increased over the past five years. However, the pandemic made a significant contribution, which, with all the quarantines and restrictions, greatly alienated people from each other and further worsened social ties that were already fragile.

In 2021, 1.3 million old people never or almost never saw their relatives, three times the number in 2017. "I have four children, nine grandchildren and four great-grandchildren, but I'm all alone. One lives in the Bordeaux region, the other in the Gard, the third in the Paris region. One lives near Lille, but she works, so she does not have time", said Denise, 81, from Hauts-de-France.

It is time to stop this shit.

-

-

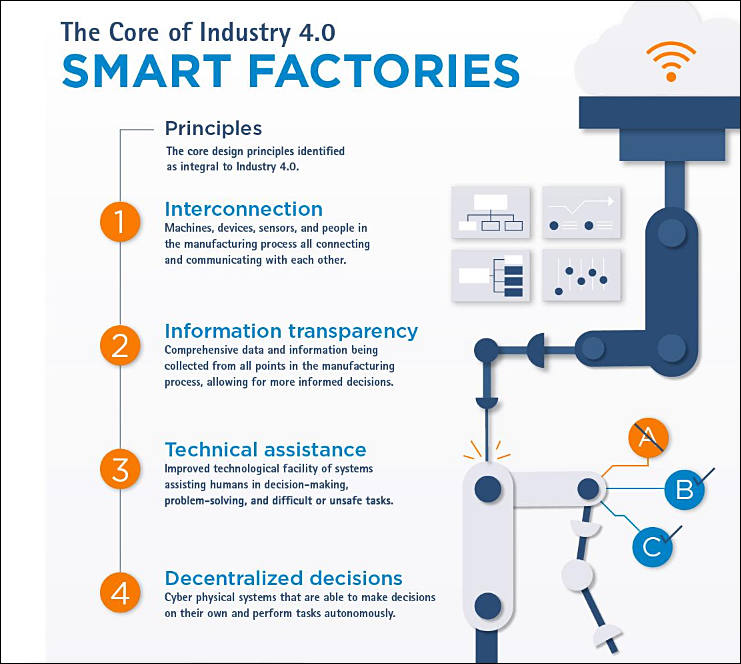

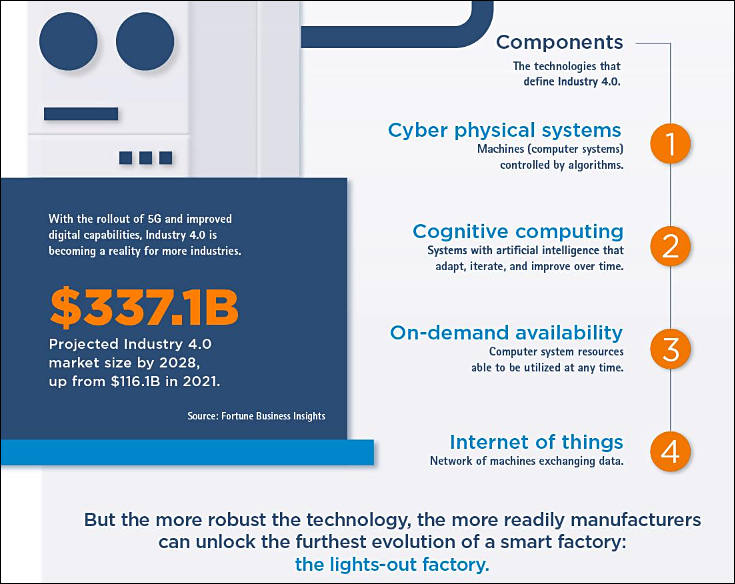

Follows0Replies1Views928War: Industry 4.0 and Robots1 comment 2 comments Vitaliy_KiselevJanuary 2022Last reply - January 2022 by Vitaliy_Kiselev

Subscribe to this blog

Subscribe to this blog

-

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List23,965

- Blog5,723

- General and News1,343

- Hacks and Patches1,151

- ↳ Top Settings33

- ↳ Beginners254

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,361

- ↳ Panasonic990

- ↳ Canon118

- ↳ Sony154

- ↳ Nikon96

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm99

- ↳ Compacts and Camcorders299

- ↳ Smartphones for video97

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras121

- Skill1,961

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors191

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips267

- Gear5,414

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,579

- ↳ Follow focus and gears93

- ↳ Sound498

- ↳ Lighting gear314

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff272

- ↳ Power solutions83

- ↳ Monitors and viewfinders339

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear560

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,319